AOKI SHUZO, is located in Uonuma city, Niigata prefecture, known as one of the snowiest regions in Japan. Established since 1717, we have been brewing Sake continuously for over 300 years. Our signature brand KAKUREI, and other Sakes are produced by various benefits of the snow country, and skilled Echigo-Toji, the master brewers. While Niigata prefecture is famous for Tanrei-Karakuchi, the light, elegant and dry Sake style, we are aiming to create Tanrei-Umakuchi, remaining the pure umami of Sake-rice, handing down our original recipe to the next 100 years.

Wago (harmonization) is valued the most when brewing sake at AOKI SHUZO. It is thought that wago among “producers” including the chief brewer, young brewers and the rice farmers, “sellers” such as liquor shops and restaurants and “drinkers” who love drinking Kakurei, brings forth the finest sake.What is behind this wago is the “spirit of enduring” and “spirit of cooperation” unique to the people of Niigata. Wago comes into power only when people are considerate of others, which sometimes include sharing patience, encouragement and pleasure.

AOKI SHUZO’s KAKUREI is well accompanied with Uonuma cuisine, strongly flavored with salt and soy sauce for the local’s who works in earnest with sweat, and to preserve fish and vegetables during the long winter. KAKUREI, has sharp and delicate Niigata Sake characteristics, but at the same time we are aiming to bring out the best of the aftertaste of umami of the rice itself, which gives fresh and new taste every time you enjoy.

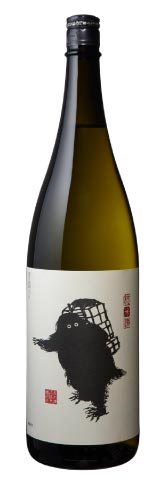

BOKUSHI SUZUKI was a merchant and an author, who is the ancestor of our brewery, born in Shiozawa, Meiwa 7 (1770). It is said KAKUREI was named by him. He wrote “Hokuetsu Seppu (Snow stories of North Etsu Province)” to describe the snowy Uonuma life. It was published after 30 years of planning, and became a bestseller of late Edo period presenting snow country’s culture, dialects, customs, traditions, Chijimi textiles, and their lifestyle. Our second signature brand YUKIOTOKO (snow Yeti), is named after the hairy strange beast that appears in the book.